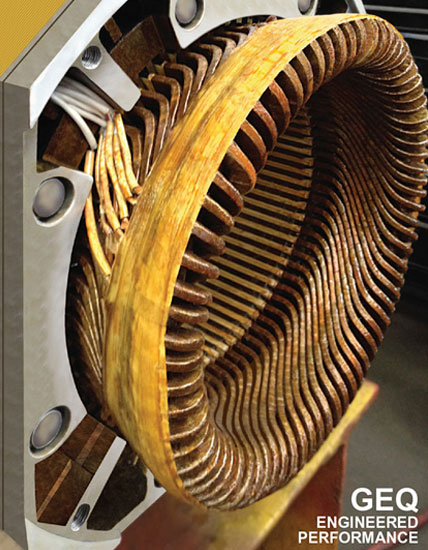

Winding Failure is the #1 Top Drive Motor Failure

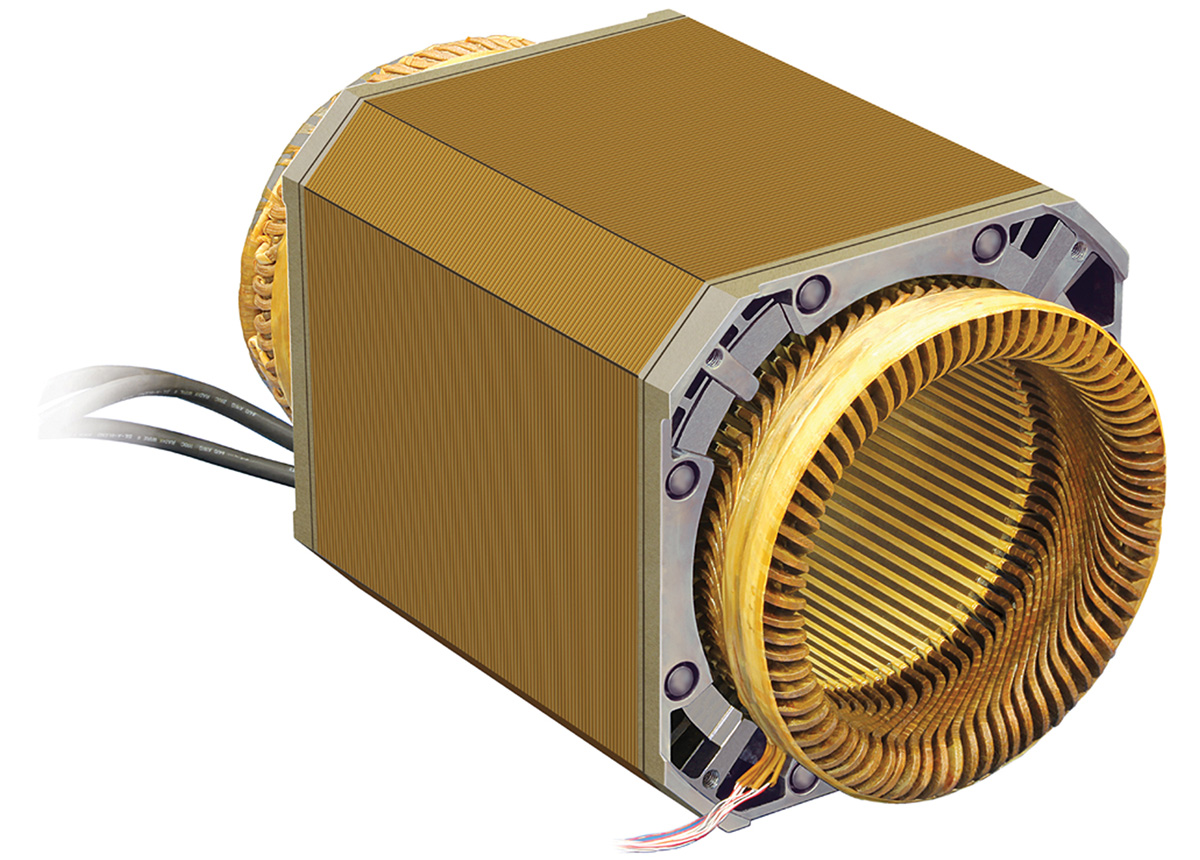

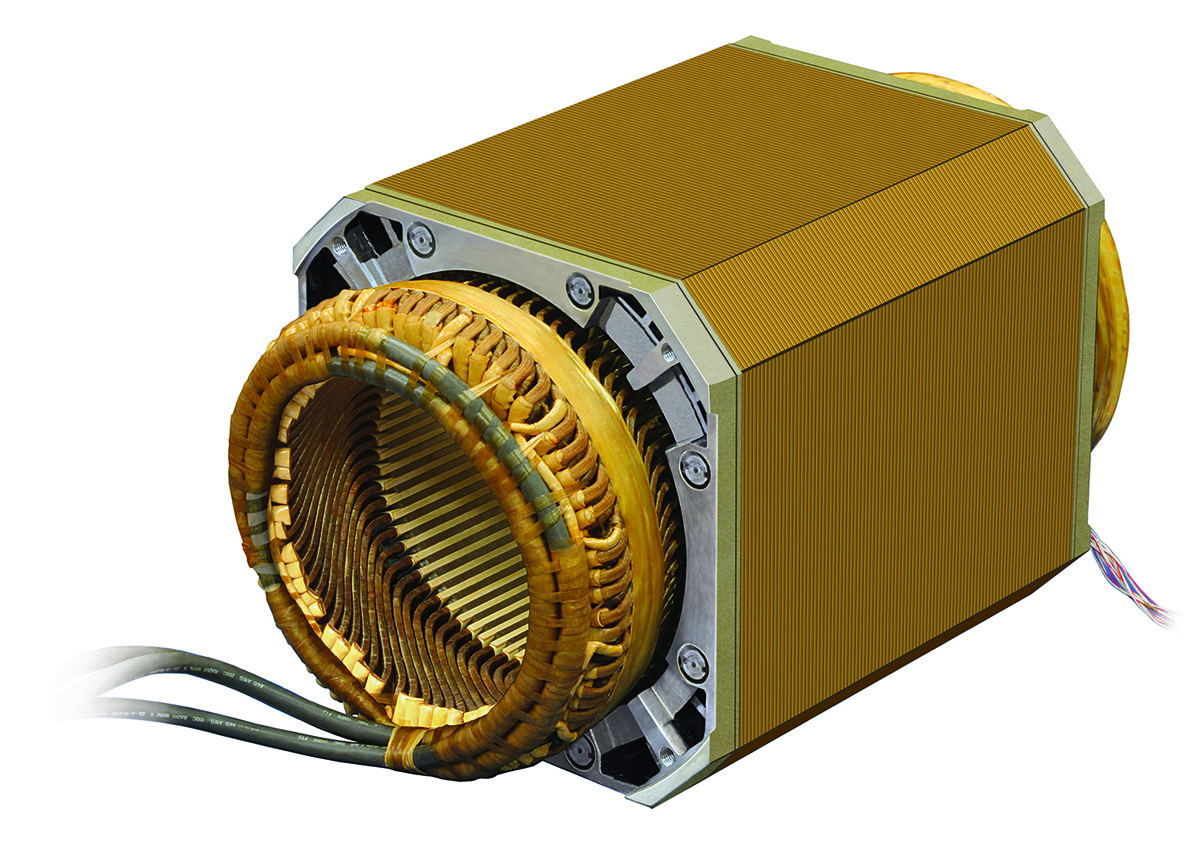

This motor stator upgrade replaces the factory random-wound motor design. GEQ manufactures the 400HP Form-Wound Motor Stator Upgrade, a technology which offers greater cooling capacity and longer motor life expectancy between top drive equipment replacement cycles. Plus, with the GEQ core exchange program (GEQ stator assets are always ready to install), downtime for motor rewind is cut from a typical 3-week rewind to a 1-week switch-out.

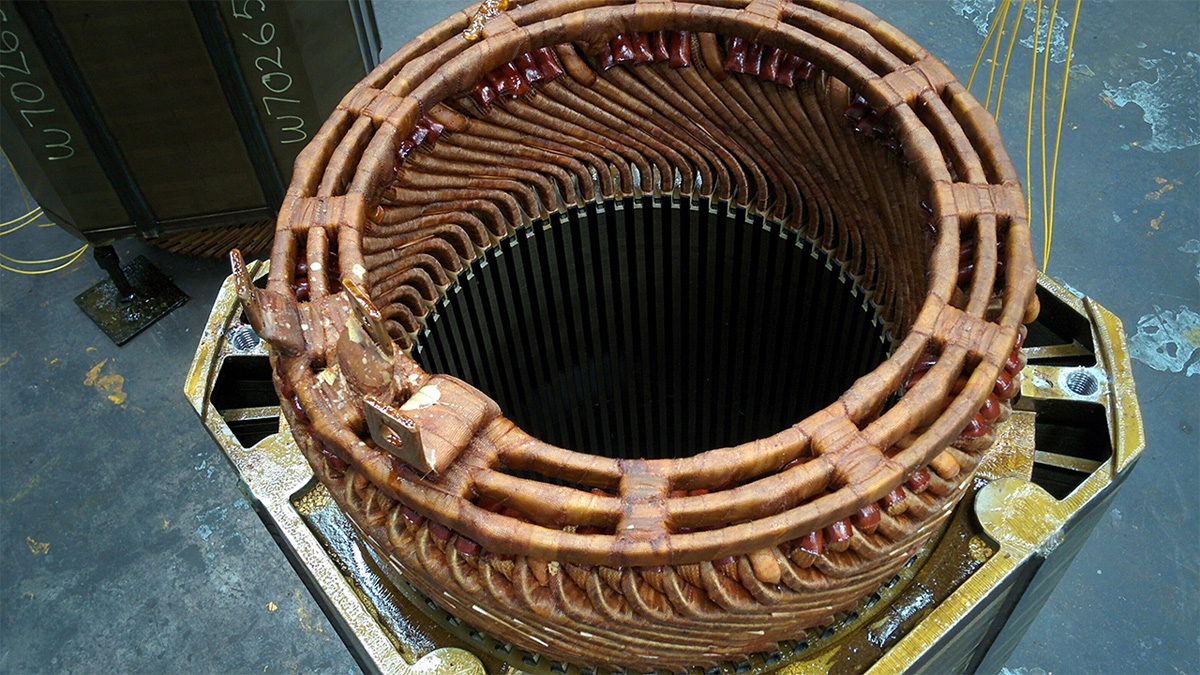

Random Wound

Weakness & Failure

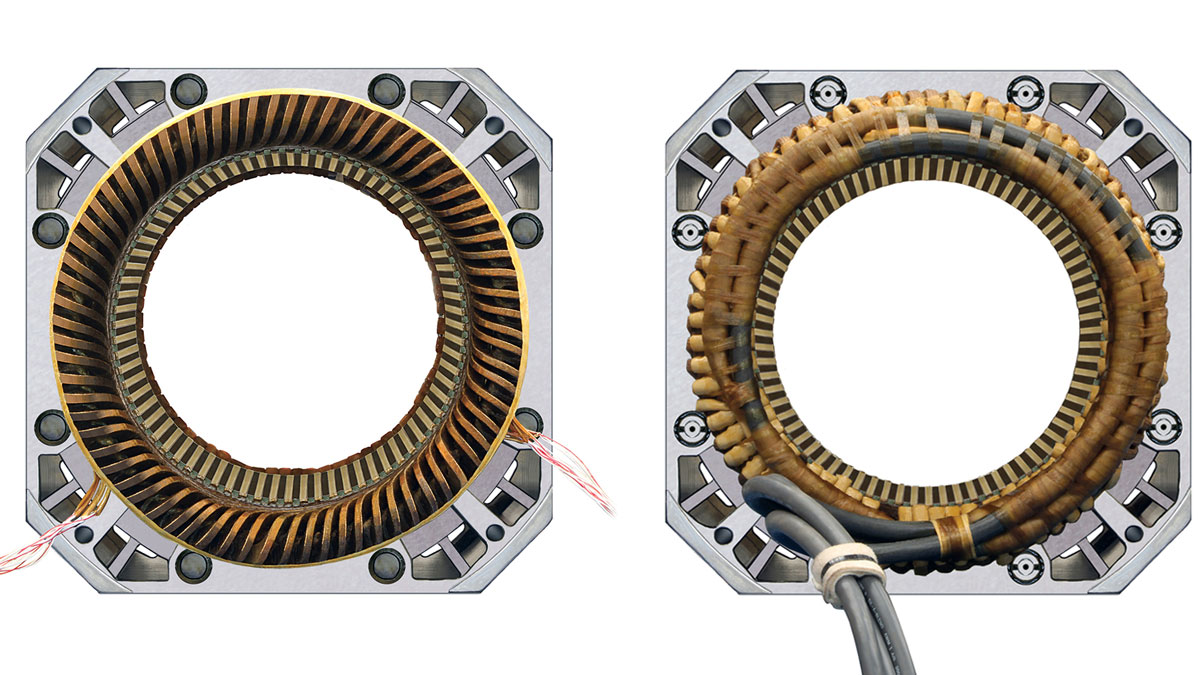

Form Wound

Strength & Endurance

About the Motor Stator Upgrade

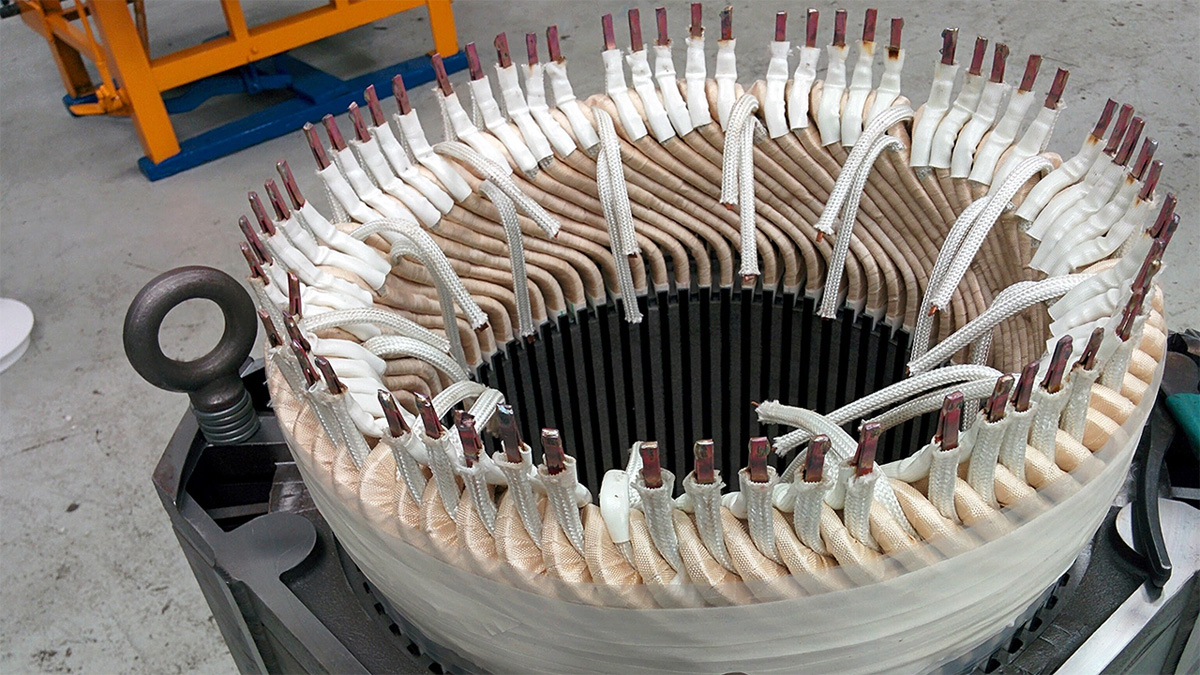

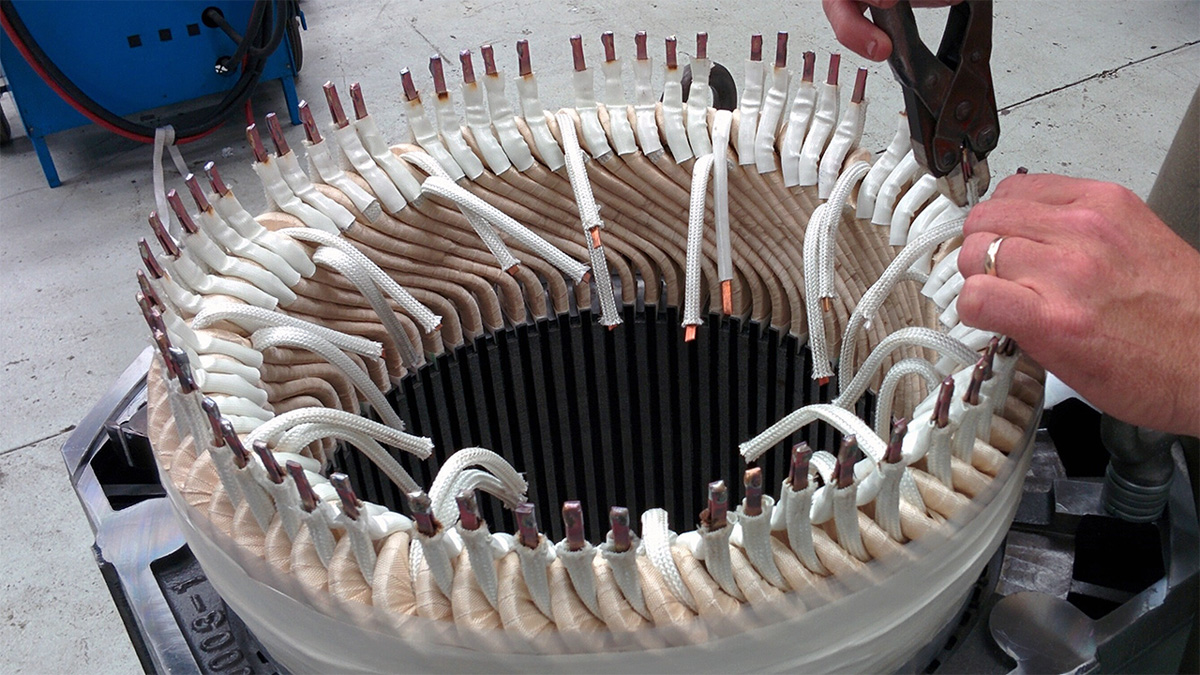

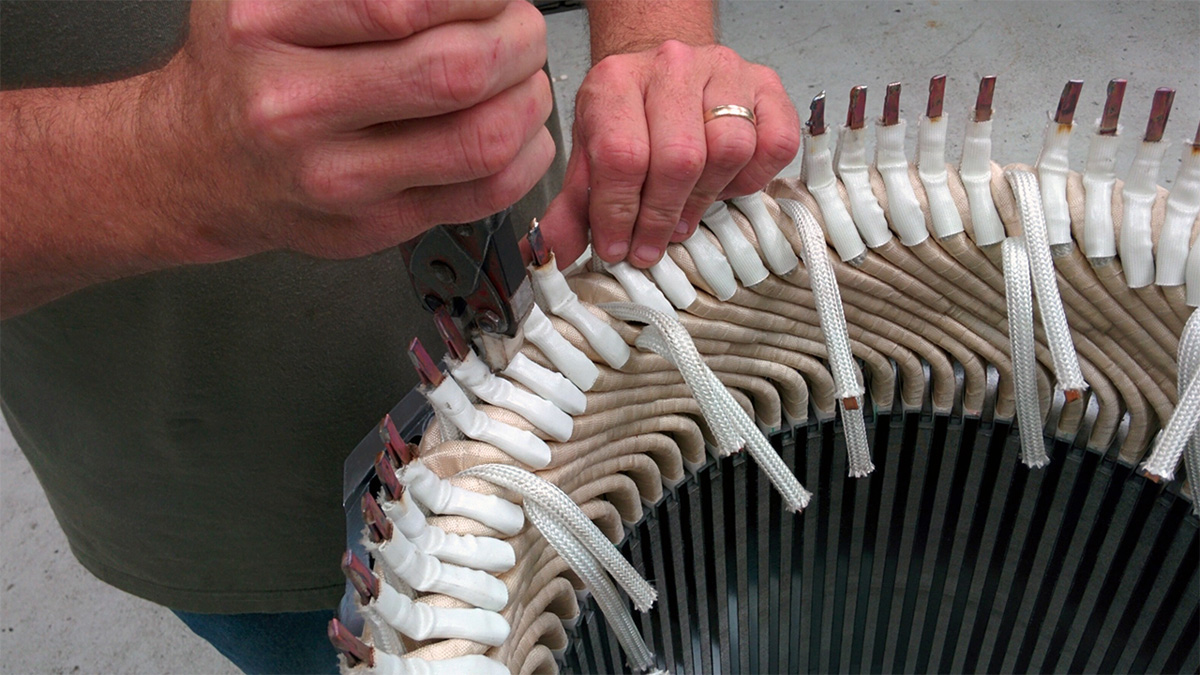

Gulf Electroquip (GEQ) developed this upgrade of the NOV TDS11 Top Drive System to overcome a common source of failures and rig shutdown - premature top drive motor failure by inferior motor design, poor insulation, excessive heat, and premature shortening within the stator windings.

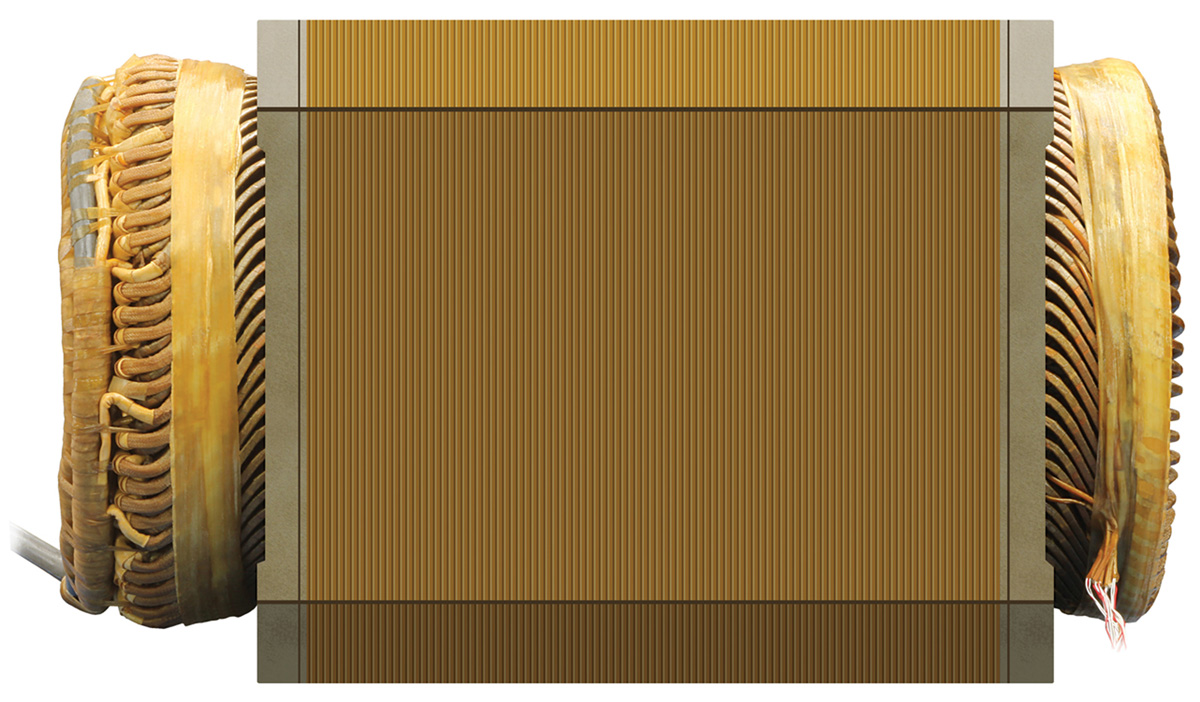

Upgrade converts the factory motor design from a random-wound motor stator design to a form-wound motor stator design, without altering the asset outer dimensions in the top drive unit. The process: OEM random wound stator out / GEQ form-wound stator in. The increased durability and longer service life provides greater certainty of performance and durability.

Features Include:

- All New Form-Wound Stator Upgrade

- Bearing upgrades available

- Resistance Temperature Detectors (RTDs) are optional

- GEQ full-load dynamometer testing available

- Class H Insulation w/Kapton, Mica Glass Tape

- Same Full-Load AMPS, Volts and Torque

- Left-Hand, Right-Hand, or Universal Configuration

- Standard Thermal Protectors

Benefits

The benefits of a remanufactured motor (vs. repaired motor) include:

- GEQ Form-Wound Stator has more cooling and a better insulating system which results in longer motor life and decreased downtime

- Less Down Time

- Quick Core Exchange