General Info

- Established in 1956

- Main Plant: Over 50,000 m^2

- Crane capacity up to >25,000 KG

- Factory authorized repair facility for major global OEMs

- Privately held company structure

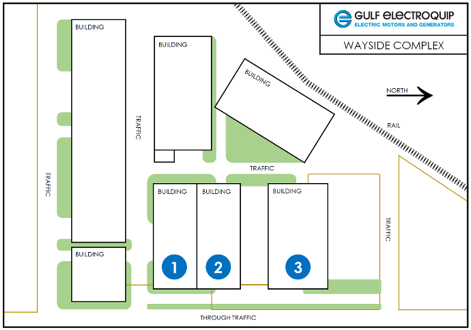

Production Facilities

- Center front three buildings (1,2 & 3) are main production facility of 20,000 m^2

- Remaining buildings are for storage and available for expansion

Complete Machine Shop Facility

Meets All Requirements for Manufacturing and Remanufacturing

- Metalworking, Machining, Fabrication

- Electrical System Components Installation

- Vacuum Pressure Impregnation - VPI

- CNC Metal Cutting

- Baking and Burning Ovens

- Sandblasting, Painting, Coating and Finishing

- Disassembly / Automated Hydrocleaning

- Assembly or Reassembly

- Rewinding

Full-Load and No-Load Services

- Perform testing to meet the criteria of ABS, DNV, Lloyd's, IEEE, UL, EASA, and IADC

- Full-Load Vertical Test Stand (Top Drives)

- Full-Load Horizontal Test Stand (Traction Motors)

- Motor Blower Test Stand (GEQ designs DNV type tested)

- Vibration Analysis (Reporting) and Balancing

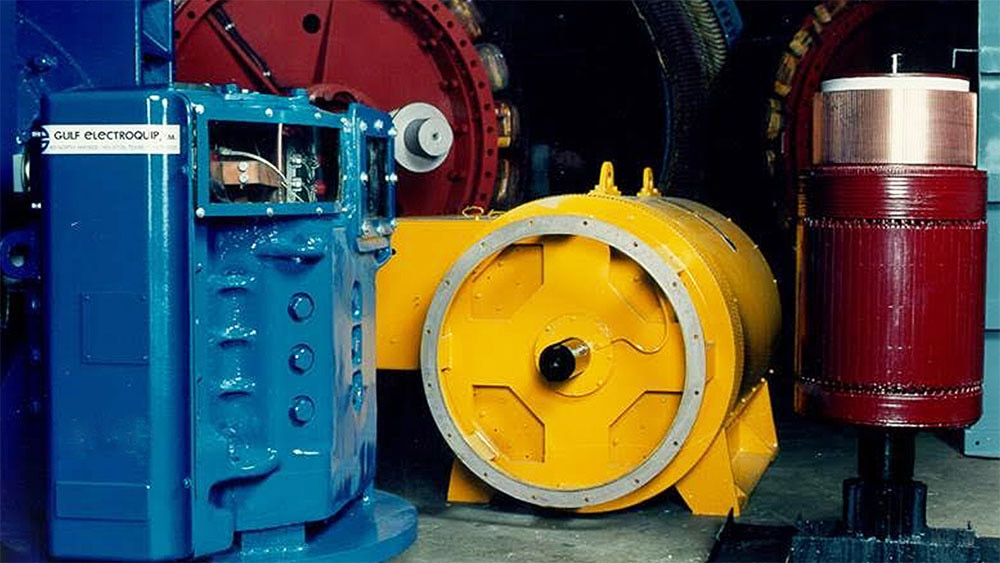

A/C & D/C Units

Motor Winding

Winding Room

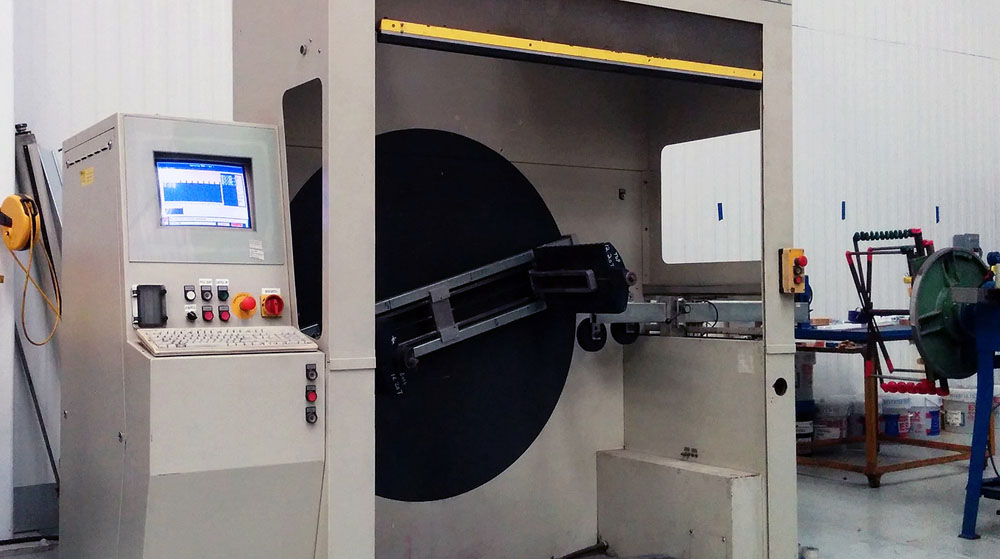

GEQ Winder

Warehouse

Warehouse

VPI Open

VPI

GEQ Technology

Storage

Storage

Drilling Motor Repair Center

Parts Counter

Motor Blowers

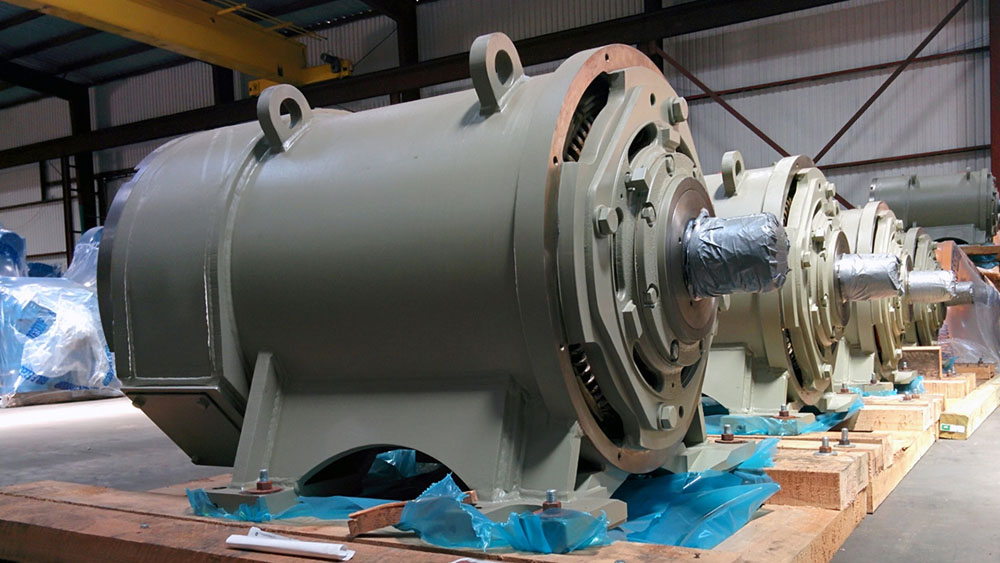

Motor Assembly

Winding Room

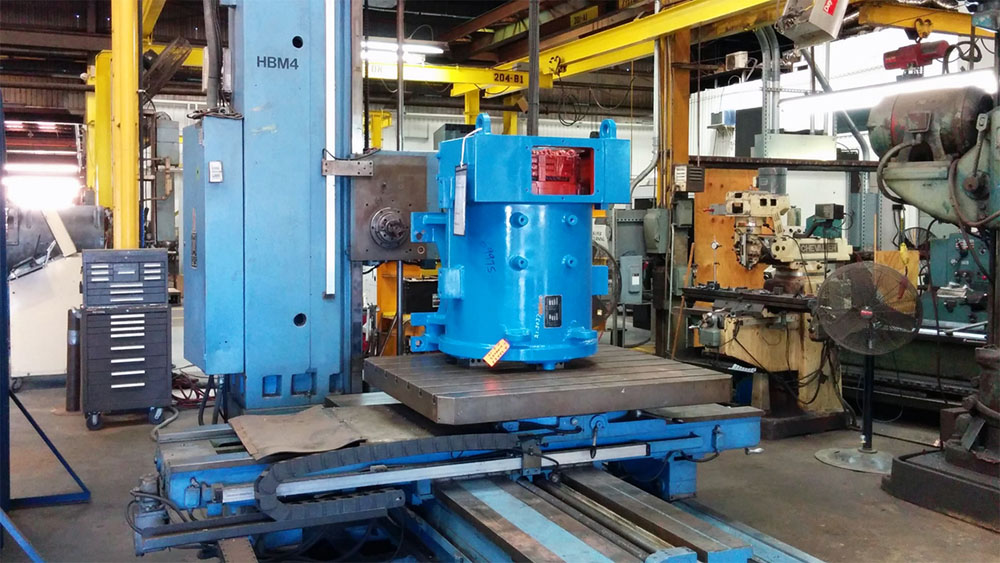

Machine Shop

Load Test Lab

Lathes

HBM4

HAAS

GE Motors

Forklift